Motor DC (theory)

DC motors convert electrical energy into mechanical torque and rotational motion. The fundamental equations are:

Torque generated:

\[\tau = k_t \cdot I\]Voltage across the motor:

\[V = k_e \cdot \omega + I \cdot R\]

Where:

\(\tau\): torque (N·m)

\(I\): current (A)

\(V\): voltage (V)

\(\omega\): angular velocity (rad/s)

\(k_t\): torque constant (N·m/A)

\(k_e\): back-EMF constant (V·s/rad)

\(R\): motor coil resistance (Ω)

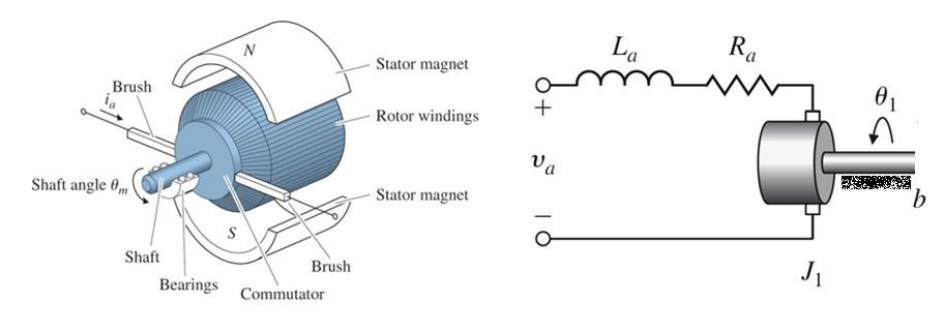

DC motor model

Parameter

va- Applied VoltageR- ResistanceL- Inductancei- Currentb- Damping coefficientJ- Rotor Inertiake- Back EMF constantkt- Torque constantθ- Rotor shaft angle

Typical Parameters for steady-state

To correctly simulate and use a DC motor in a control system, you must know or estimate the following key parameters:

Symbol |

Quantity |

Units |

Typical Range (Lab Motors) |

|---|---|---|---|

\(\tau\) |

Torque |

N·m |

0.01 – 0.2 N·m |

\(I\) |

Current |

A |

0.2 – 2 A |

\(V\) |

Voltage |

V |

3 – 24 V |

\(\omega\) |

Angular speed |

rad/s |

100 – 2000 rad/s |

\(k_t\) |

Torque constant |

N·m/A |

0.01 – 0.1 N·m/A |

\(k_e\) |

Back-EMF constant |

V·s/rad |

0.01 – 0.1 V·s/rad |

\(R\) |

Coil resistance |

Ω |

0.5 – 10 Ω |

Most of these values are provided in the motor’s datasheet:

\(k_t\) and \(k_e\): Often given directly. For brushed motors, these are numerically equal (\(k_t = k_e\)) if using SI units.

Stall torque (\(\tau_{\text{stall}}\)): Maximum torque at zero speed.

No-load speed (\(\omega_{\text{free}}\)): Speed at zero torque.

Stall current (\(I_{\text{stall}}\)): Current at zero speed and maximum torque.

Resistance: \(R = V_{\text{stall}} / I_{\text{stall}}\)

From these, you can compute:

\(k_t = \tau_{\text{stall}} / I_{\text{stall}}\)

\(k_e = V_{\text{free}} / \omega_{\text{free}}\)

Trade-Offs in Motor Selection

The performance of a DC motor is a balance between torque and speed. Key considerations:

Higher torque → requires more current.

Higher speed → increases back-EMF and voltage needs.

Higher current → increases resistive losses (\(I^2 R\)) and risk of overheating.

Motor constants (\(k_t\), \(k_e\)) are typically fixed for a given model.

Always respect maximum ratings: exceeding current, voltage, or power may permanently damage the motor.

Dynamical model

Electrical part

\(va = R i + L \frac{di}{dt} + k_e \frac{dθ}{dt}\)

Electromechanical Conversion

\(T_{m} = k_t i\)

Mechanical Part (inertia plus load)

\(T_{m} = b \frac{dθ}{dt} + J\frac{d^2θ}{dt^2}\)

If required, mechanical part can also include Coulomb (static) or Reynolds (aerodynamic) friction

DC motor - regime estacionário

There are two time constants associated to DC motors in the second order model:

the electrical time constant \(tau_{el}=L/R\), of order 0.1 ms

the mechanical time constant \(tau_{mech}=J/B\), of order 100 ms

In many if not most control projects, a stationary (steady state) model is adequate.

By zeroing the time variations (dynamic derivatives):

The electrical part becomes

The mechanical part becomes

A typical (minimal) load:

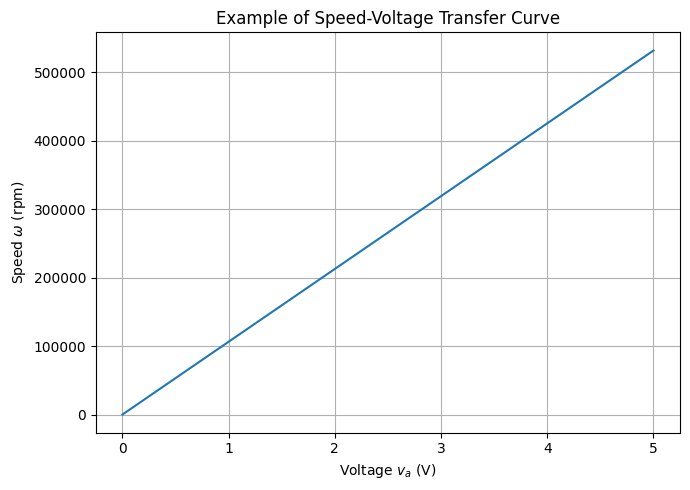

Speed-voltage transfer curve

This linear correlation between speed \(\omega\) and applied Voltage \(va\) is called the speed-voltage transfer curve.

For a given motor, the proportionality constant is given by

[10]:

import numpy as np

import matplotlib.pyplot as plt

# Voltage range

va = np.linspace(0, 5, 100)

# Electrical & mechanical parameters (typical/representative)

R = 2.7e0 # Armature resistance [ohm]

B = 3.0e-8 # Viscous damping coeff. [N·m·s/rad]

ke = 7.5e-4 # Back-EMF constant [V·s/rad] (== V/(rad/s))

kt = 7.5e-4 # Torque constant [N·m/A] (≈ ke in SI)

# Speed-voltage static transfer curve

propconst= 1 / ((1 + (R * B) / (ke * kt)) * ke)

print(propconst)

omega = propconst*va*60/6.28

plt.figure(figsize=(7, 5))

plt.plot(va, omega*60/6.28)

plt.xlabel('Voltage $v_a$ (V)')

plt.ylabel('Speed $\\omega$ (rpm)')

plt.title('Example of Speed-Voltage Transfer Curve')

plt.grid(True)

plt.tight_layout()

plt.show()

1165.5011655011656

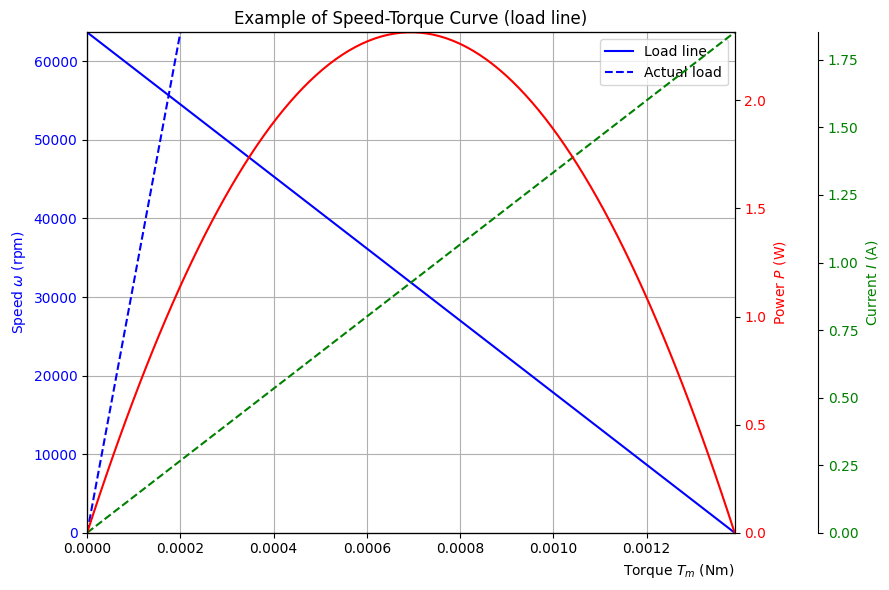

Speed-Torque Curve (load line)

This linear inverse correlation between speed \(\omega\) and torque \(T_m\) is called the load line.

For a given motor:

the slope \(-\frac{R}{k_e k_t}\) is constant.

the vertical offset \(\frac{va}{k_e}\) is proportional to the applied Voltage

Load line reference points:

Maximum speed at zero load and torque:

Maximum torque at full load and zero speed:

The point of maximum energy transfer is in the center point of the load line:

[8]:

import numpy as np

import matplotlib.pyplot as plt

# Parameters

va = 5 #applied voltage

# Torque range

Tm = np.linspace(0,kt*va/R , 100)

# Electrical & mechanical parameters (typical/representative)

R = 2.7e0 # Armature resistance [ohm]

B = 3.0e-8 # Viscous damping coeff. [N·m·s/rad]

ke = 7.5e-4 # Back-EMF constant [V·s/rad] (== V/(rad/s))

kt = 7.5e-4 # Torque constant [N·m/A] (≈ ke in SI)

# Speed-torque curve

omega = va/ke - R / (ke * kt) * Tm

# Current curve

Im=Tm/kt

# Power curve

P = omega * Tm

# Set axis limits

x_min, x_max = Tm.min(), Tm.max()

y_min, y_max = omega.min()*60/6.28, omega.max()*60/6.28

p_min, p_max = P.min(), P.max()

I_min, I_max = Im.min(), Im.max()

fig, ax1 = plt.subplots(figsize=(9, 6))

# Main plot: Torque vs Speed

ax1.plot(Tm, omega*60/6.28, label='Load line', color='b')

ax1.plot(Tm, Tm/B*60/6.28, label='Actual load', color='b', linestyle='--')

ax1.set_ylabel('Speed $\\omega$ (rpm)', color='b')

ax1.tick_params(axis='y', labelcolor='b')

ax1.set_xlabel('Torque $T_m$ (Nm)', loc='right')

ax1.xaxis.set_label_position('bottom')

ax1.xaxis.set_ticks_position('bottom')

ax1.spines['bottom'].set_position(('outward', 0))

ax1.set_xlim(x_min, x_max)

ax1.set_ylim(y_min, y_max)

# Additional y-axis for Current

ax3 = ax1.twinx()

ax3.plot(Tm, Im, label='Current', color='g', linestyle='--')

ax3.spines['right'].set_position(('outward', 60))

ax3.yaxis.set_label_position('right')

ax3.yaxis.set_ticks_position('right')

ax3.set_ylim(ax1.get_ylim())

#omega_ticks = ax1.get_yticks()

#ax3.set_yticks(omega_ticks)

#ax3.set_yticklabels([f"{(ke*tick/(60/6.28) ):.1f}" for tick in omega_ticks])

ax3.set_ylabel('Current $I$ (A)', color='g')

ax3.tick_params(axis='y', labelcolor='g')

ax3.set_ylim(I_min, I_max) # restrict power axis to min/max

# Additional y-axis for Power

ax4 = ax1.twinx()

ax4.plot(Tm, P, label='Power', color='r')

ax4.set_ylabel('Power $P$ (W)', color='r')

ax4.tick_params(axis='y', labelcolor='r')

ax4.set_ylim(p_min, p_max) # restrict power axis to min/max

# Grid on both x and y axes

ax1.grid(True, which='both', axis='both')

ax1.legend()

#ax4.legend()

plt.title('Example of Speed-Torque Curve (load line)')

plt.tight_layout()

plt.show()

Gears

Gears can be used to adapt motor output to desired speed and torque levels.

Basic Gear Equations

Gear ratio:

\[R = \frac{N_{\text{out}}}{N_{\text{in}}}\]where \(N\) is the number of teeth or diameter.

Output torque:

\[\tau_{\text{out}} = R \cdot \tau_{\text{in}}\]Output speed:

\[\omega_{\text{out}} = \frac{\omega_{\text{in}}}{R}\]

Why Use Gears?

Increase torque at the cost of lower speed.

Reduce load on the motor to avoid overheating.

Match the dynamics of the controlled system (e.g. pendulum).

Pulleys (with belts) provide similar mechanical advantages as gears.They are quieter than gears, and the distance between shafts is more flexible, so systems with pulleys and belts are more simple to design and align. At the same time, they are less precise (risk of belt slippage), and limited to moderate torque applications.

Numerical Example: Gear Matching

Suppose your pendulum needs:

Torque of \(0.1\) N·m

Speed around \(30\) rad/s

But your available motor produces:

Torque of \(0.02\) N·m

Speed of \(150\) rad/s

Then use a gear ratio of:

This brings output torque up to \(0.1\) N·m, and reduces speed to:

Typical values

[9]:

# Typical small 3.7 V brushed coreless drone motor (e.g., 8.5×20 mm “8520”)

# SI units throughout.

# Electrical & mechanical parameters (typical/representative)

R = 2.7e0 # Armature resistance [ohm]

B = 3.0e-8 # Viscous damping coeff. [N·m·s/rad]

ke = 7.5e-4 # Back-EMF constant [V·s/rad] (== V/(rad/s))

kt = 7.5e-4 # Torque constant [N·m/A] (≈ ke in SI)

# Convenience

import math

V_nom = 3.7 # nominal test voltage [V]

# Proportionality from DC voltage to angular speed at no external load:

# Steady-state with viscous friction only:

# V = I*R + ke*ω, kt*I = B*ω → I = (B/kt)*ω

# ⇒ V = (R*B/kt + ke) * ω ⇒ ω/V = 1 / (ke + R*B/kt)

omega_per_volt = 1.0 / (ke + R*B/kt) # [rad/s per V]

rpm_per_volt = omega_per_volt * 60.0 / (2*math.pi) # [RPM per V]

# Nominal no-load speed at V_nom

omega_0 = omega_per_volt * V_nom

rpm_0 = rpm_per_volt * V_nom

# Some sanity checks

I_stall = V_nom / R # [A]

T_stall = kt * I_stall # [N·m]

# At no-load, I ≈ (B/kt)*ω

I_noload = (B/kt) * omega_0 # [A]

T_friction= kt * I_noload # [N·m] (equals B*ω0)

vals = {

"R_ohm": R,

"B_Nm_s_per_rad": B,

"ke_Vs_per_rad": ke,

"kt_Nm_per_A": kt,

"omega_per_volt_rad_s_per_V": omega_per_volt,

"rpm_per_volt_RPM_per_V": rpm_per_volt,

"no_load_speed_rpm_at_3p7V": rpm_0,

"stall_current_A_at_3p7V": I_stall,

"stall_torque_Nm_at_3p7V": T_stall,

"no_load_current_A_est": I_noload,

"friction_torque_Nm_est": T_friction,

}

for k, v in vals.items():

print(f"{k}: {v:.6g}")

R_ohm: 2.7

B_Nm_s_per_rad: 3e-08

ke_Vs_per_rad: 0.00075

kt_Nm_per_A: 0.00075

omega_per_volt_rad_s_per_V: 1165.5

rpm_per_volt_RPM_per_V: 11129.7

no_load_speed_rpm_at_3p7V: 41180

stall_current_A_at_3p7V: 1.37037

stall_torque_Nm_at_3p7V: 0.00102778

no_load_current_A_est: 0.172494

friction_torque_Nm_est: 0.000129371